The Klaus Tunnel Chain: DSI Ground Support Products stabilize Excavation of the new Eastern Tubes

The A 9 Pyhrn Motorway in Austria is an important North South link. One of its sections is the Klaus Tunnel Chain. The approx. 8km long section of the A 9 is located around 130km east of Salzburg and was originally built with one lane in each direction. At the end of 2013, the completion of the section began with the construction of new bridges that also served as access roads for the construction of the second tunnel tubes.

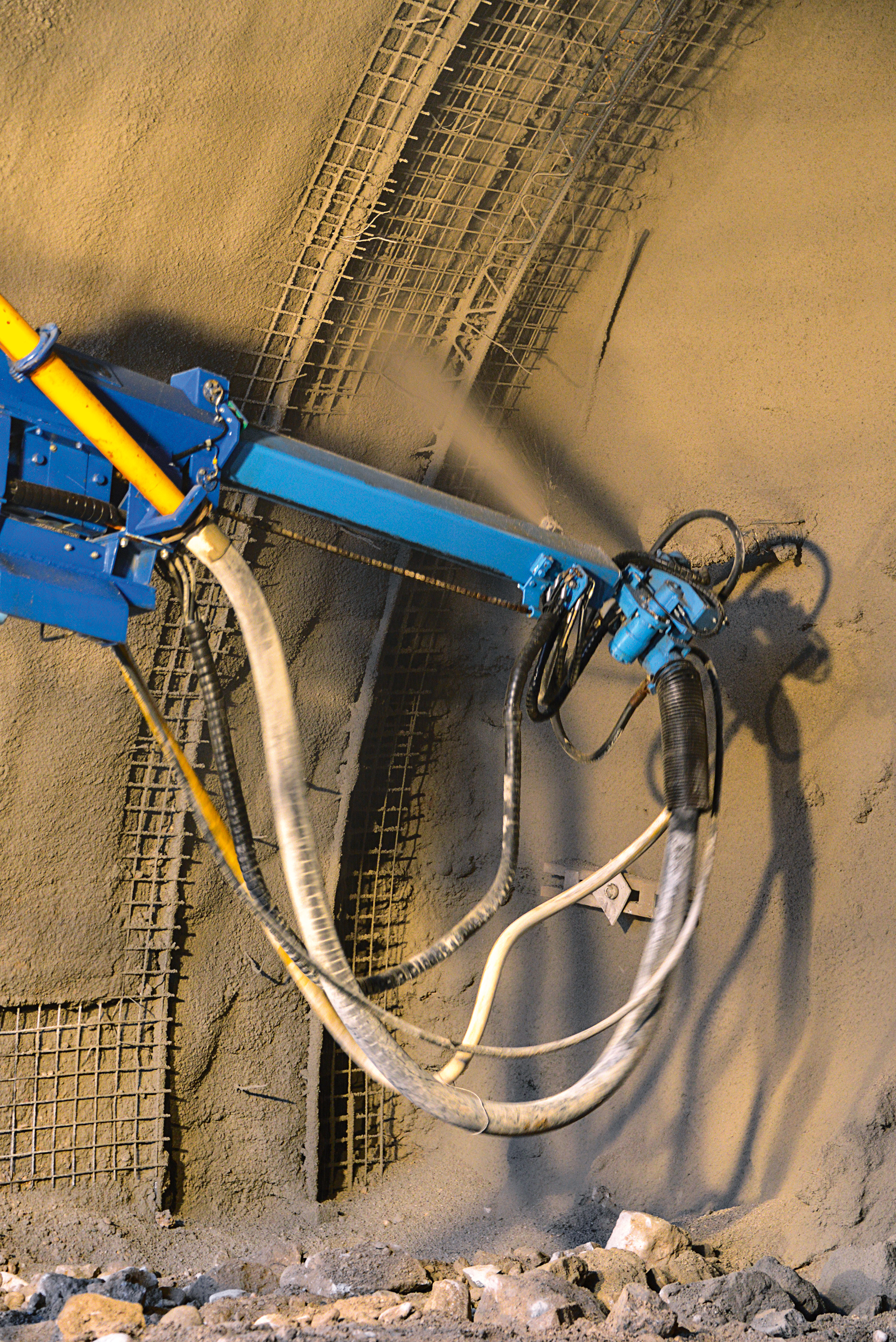

Section 4 included the eastern tube of the 2.2km long Klauser Tunnel as well as the eastern tube of the 0.4km long Traunfried Tunnel. The Klauser Tunnel is being excavated from an intermediate heading, with a 28 and a 70m long section in the North being built using the open cut method and a 36m long section being built using the cut-and-cover method. The actual excavation work of the 1,857m long tunnel started in May 2015 and is being realized using the mining construction method.The crown of the eastern tube was driven in advance because it served as an escape route for the existing western tube. Bench and invert heading were used for driving the tunnel. The excavation of the Traunfried tunnel was carried out successively in crown, bench and invert.For stabilizing the tunnel driving work in both tunnels, DSI supplied the following high quality ground support products:

- OMEGA-BOLT® Expandable Friction Bolts with anchor plates

- 25mm Ø SN Anchors in lengths of 2, 3, 4 and 6m

- R32-250 Ø and R 32-280 DSI Hollow Bar Anchor System in lengths of 2, 3 and 4m

- R32-250 Ø DSI Self-Drilling Spiles

- 25 mm Ø steel spiles in lengths of 3 and 4m

- Type AT – 114 Pipe Umbrella System with threaded connections including drilling unit and accessories

The 2.9km long Spering Tunnel as well as the 0.8km long Falkenstein Tunnel are located in section 5. Carbonate rock with gravel, limestone and clay marl prevail in this part of the northern Tyrolese limestone Alps. The Eastern tube of the Spering Tunnel was excavated using bench and invert heading along the complete tunnel length. In two locations, the tunnel tube was widened to accommodate cutouts. The new and the existing tunnel tube are connected via 8 walkable and 2 drivable crosscuts. At the eastern tube of the Falkenstein Tunnel, excavation and stabilization are carried out in the total cross section. Here, both tunnel tubes are connected via 2 walkable crosscuts. In both of these tunnels, the following ground support products were used for safe excavation in partly brittle rock:

- OMEGA-BOLT® Expandable Friction Bolts with anchor plates

- 25mm Ø SN Anchors in lengths of 2, 3, 4 and 6m

- R32-250 Ø and R 32-280 DSI Hollow Bar Anchor System in lengths of 4, 6 and 12m

- 25 mm Ø steel spiles in lengths of 3 and 4m

- R32-210 Ø, 3m long IBO Self-Drilling Spiles

- Lattice girders incl. angle connections and accessories

- Arches

- Type AT – 114 Pipe Umbrella System with threaded connections including drilling unit and accessories

With the help of the ground support products supplied by DSI, all of the tunnel tubes were excavated safely and within the planned schedule.