Long-term Use of DSI TenCate Recovery Mat System at the Springvale Underground Mine

Centennial Coal is one of the principal fuel suppliers to the energy industry in the Australian federal state of New South Wales. Since 2005, the company has been successfully using DSI’s TenCate mat system for safe longwall recovery in their Springvale Underground Mine located west of Sydney.

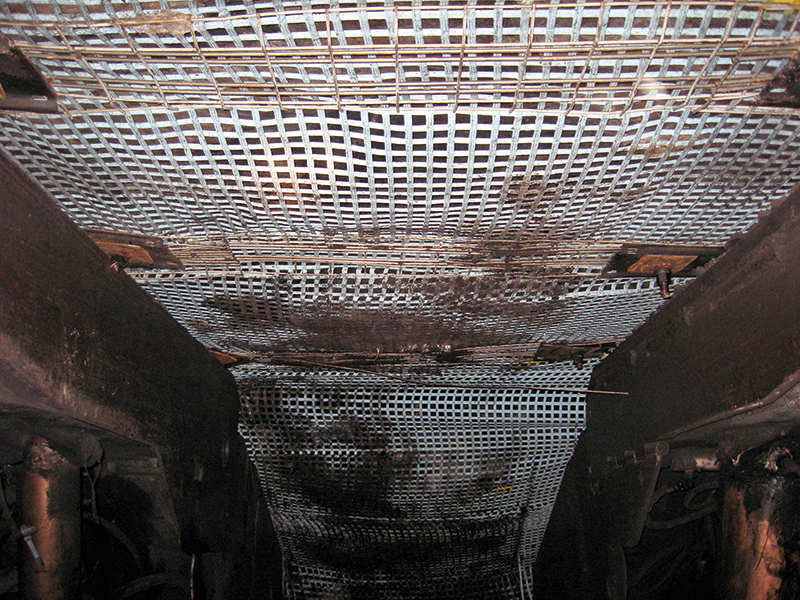

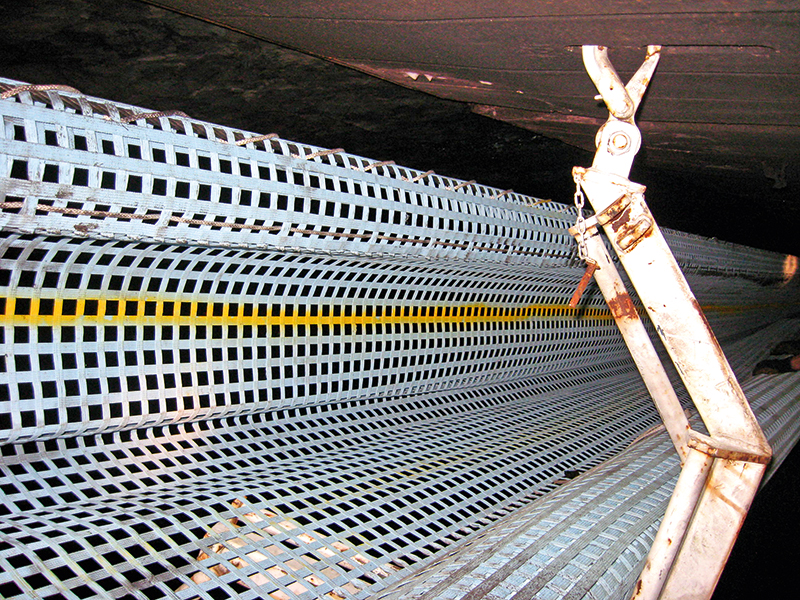

Longwall mining is a method for exploiting underground coal seams. Relocation of the longwall mining equipment is made easier by a polyester geo grid developed by DSI Australia. The grid is placed over the longwall shields to facilitate their safe removal. The system provides a barrier between the loose material in the goaf and the drive in which the miners remove the equipment.

The TenCate geo grid system has been developed with input from Australian and international underground coal miners to withstand the extreme load conditions experienced in underground mines. It has been tested by the state of New South Wales’ Department of Mineral Resources for electrical and fire resistance and is certified Flame Resistant and Anti-Static (FRAS).

TenCate geo grids are available with different tensile strengths for flexible use. At the Springvale Mine, a geo grid with a tensile strength of 600/400kN is used behind the caving shields, and the 300/200kN variant is extended over the canopies and down the face. Centennial Coal have also used a DSI-supplied 80/80kN mat for the face section in their Springvale mine.

According to Paul Rutzou, Technical Services Manager at the Springvale underground mine, it is the mat’s proven safety and operational efficiency characteristics combined with DSI Australia’s willingness to get involved with the job that resulted in the decision to use the TenCate System on a long-term basis: “It’s a good product, it works very well and it’s well supported by the company. Both the high quality mat and the excellent customer service help us get the shield recovery program completed on time and on budget.”

According to Paul Rutzou, the fact that the TenCate System is available in different tensile strengths is a considerable advantage: Rather than being restricted to the standard 600/400kN mat, 200/300kN tensile mats can be used in certain sections, which significantly reduces the mat’s size and weight and improves handling.

DSI Australia’s support package also includes site inspection and an examination of geological conditions. The results determine the geo grid size and the suitable method used for the overall installation process. DSI employees also offer on-site advice on the most appropriate installation technique to maximize the overall efficiency of the program. The service package is completed by crew training as well as pre- and post-installation reports.

The mat is supplied to Springvale Mine on 17m wide and 315m long rolls on an extended skid – an outcome of DSI’s continuous post-installation improvement program made possible by customer support after installation. Additionally, as a result of Centennial Coal’s requirements, the main gate end has been adapted to facilitate manual handling underground.